Heating reservoir

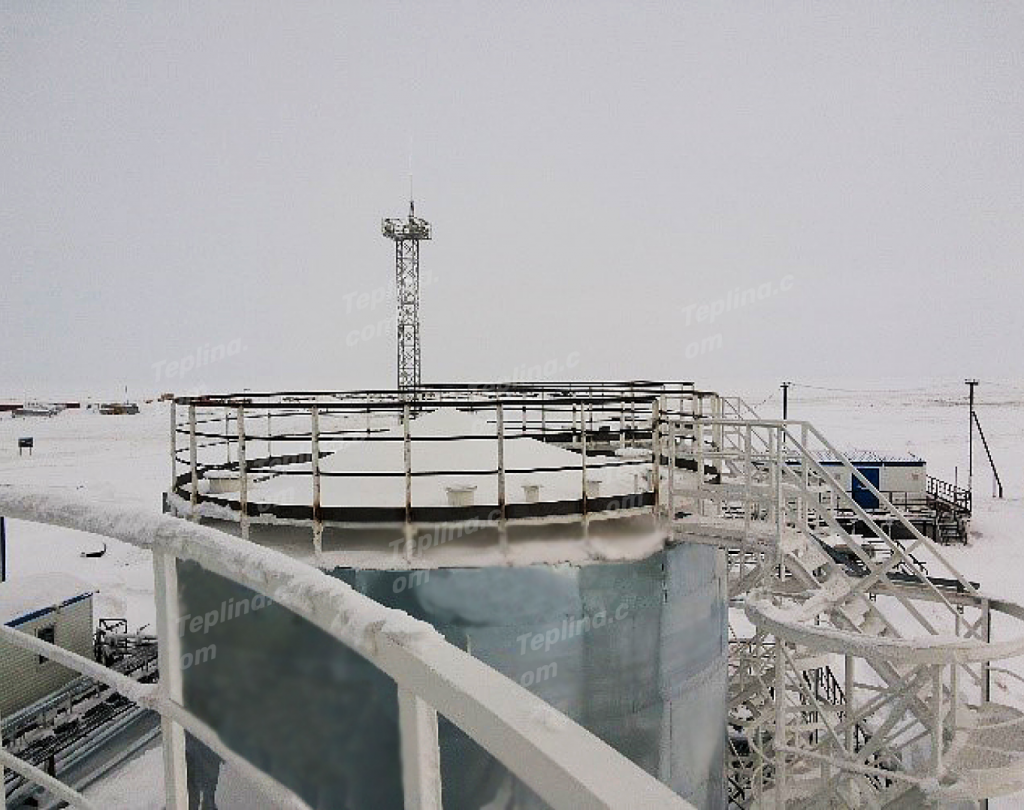

Heating system: frost protection and temperature maintenance of reservoirs

In the oil and petrochemical industries in tanks at low temperatures, the viscosity of oil and liquids increases, which leads to the solidification (thickening) of the product and the precipitation of solid fractions In the food industry, the task of heating tanks to maintain the temperature of liquid products, such as palm oil, etc., is relevant. Company "Online Energy" suggests heating systems for reservoirs, tanks and capacities with crude oil, diesel fuel and other liquids will ensure the maintenance of the required process temperature and eliminate the negative effects of lowering the temperature. Fill out questionnaries of reservoir heating and our managers help you to choose optimal solution taking into account all necessary conditions of heating task. Qualified design and installation of the reservoir heating will avoid unnecessary costs for the purchase of equipment, installation and maintenance of the heating system, and ensure reliable operation of the system for many years.

In the oil and petrochemical industries in tanks at low temperatures, the viscosity of oil and liquids increases, which leads to the solidification (thickening) of the product and the precipitation of solid fractions In the food industry, the task of heating tanks to maintain the temperature of liquid products, such as palm oil, etc., is relevant. Company "Online Energy" suggests heating systems for reservoirs, tanks and capacities with crude oil, diesel fuel and other liquids will ensure the maintenance of the required process temperature and eliminate the negative effects of lowering the temperature. Fill out questionnaries of reservoir heating and our managers help you to choose optimal solution taking into account all necessary conditions of heating task. Qualified design and installation of the reservoir heating will avoid unnecessary costs for the purchase of equipment, installation and maintenance of the heating system, and ensure reliable operation of the system for many years.

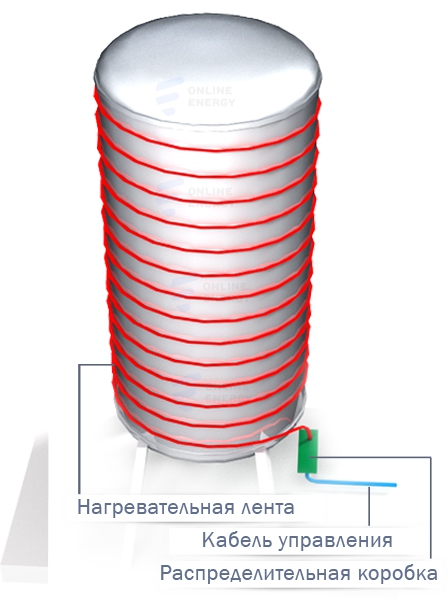

Systems of heating and temperature maintenance of reservoirs, suggested by company "Online Energy"

- Cable heating of tanks with a self-regulating cable.

- Resistive cable heating of tanks and vessels.

- ENGL electrical flexible tapes for heating tanks, cisterns and containers.

Cable heating of tanks, cisterns

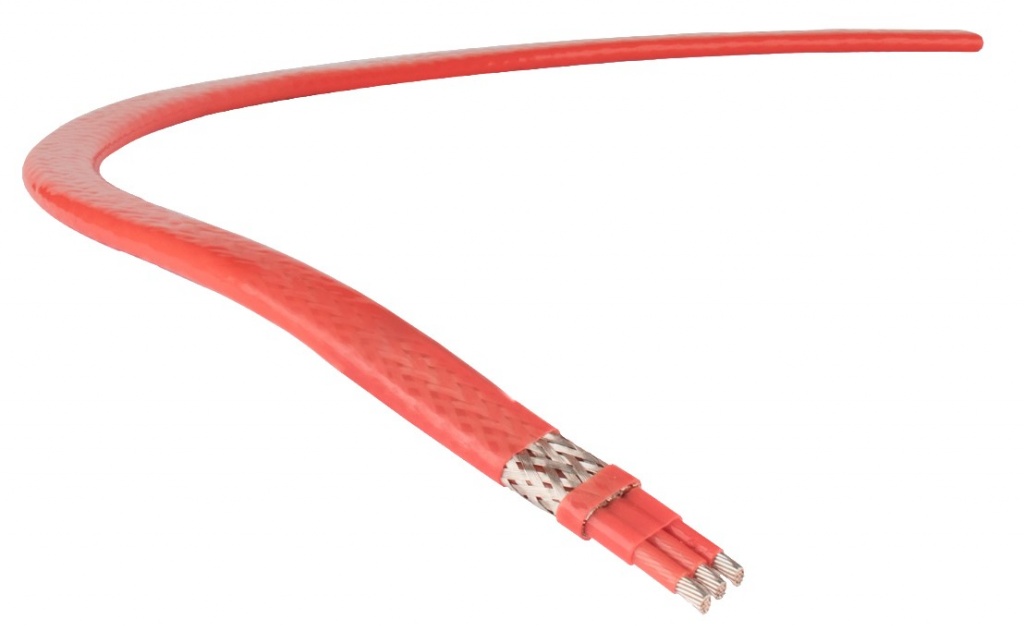

For cable heating of tanks in industry, a company "Online Energy" suggest self-regulated and resistive heating cable Thermon и heating cable Eltherm. Differences between resistive and self-regulating cables In a resistive cable, heat is generated due to ohmic losses in the heating core of the cable. The cable, in addition to the heating cable, may contain a conductive core, which simplifies its connection scheme. The thermal power of resistive cables is practically independent of temperature. To ensure long-term and reliable operation of these types of cables, it is important to comply with the calculated heat transfer conditions so as not to cause overheating.

For cable heating of tanks in industry, a company "Online Energy" suggest self-regulated and resistive heating cable Thermon и heating cable Eltherm. Differences between resistive and self-regulating cables In a resistive cable, heat is generated due to ohmic losses in the heating core of the cable. The cable, in addition to the heating cable, may contain a conductive core, which simplifies its connection scheme. The thermal power of resistive cables is practically independent of temperature. To ensure long-term and reliable operation of these types of cables, it is important to comply with the calculated heat transfer conditions so as not to cause overheating.

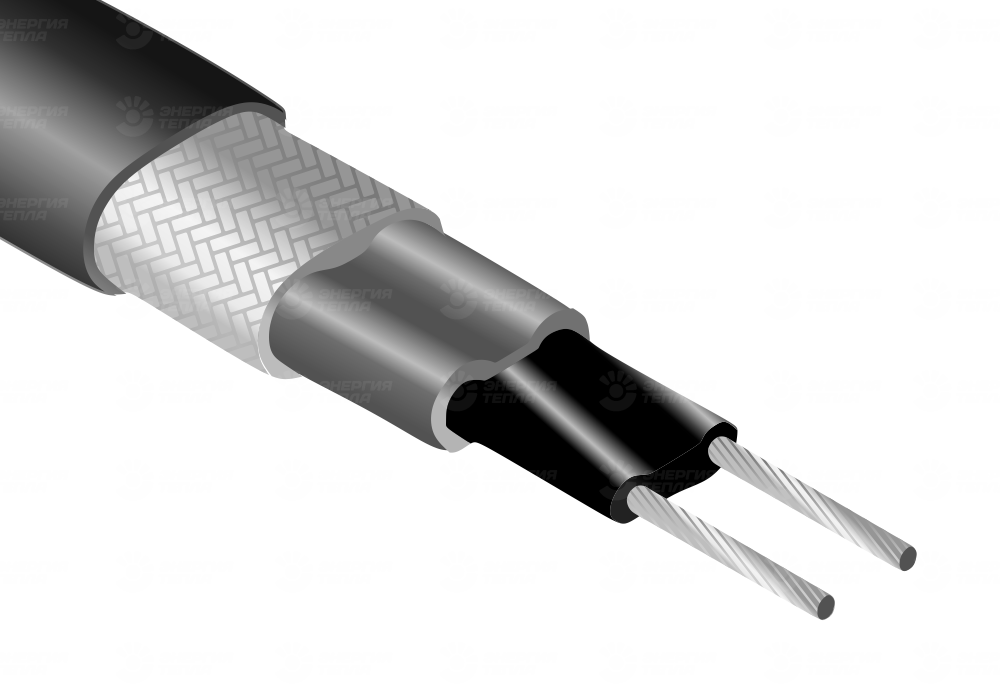

Self-regulated cabel has two parallel conductive conductors, the gap between which is filled with a special semiconductor compound, which changes its resistance depending on temperature. Thanks to the self-regulating effect, the heating cable emits the more heat, the lower the temperature of the tank, its temperature decreases with increasing temperature. Thus, it saves electricity and never burns out, even with self-intersection. The self-regulation property allows the creation of safe tank heating systems.

Self-regulated cabel has two parallel conductive conductors, the gap between which is filled with a special semiconductor compound, which changes its resistance depending on temperature. Thanks to the self-regulating effect, the heating cable emits the more heat, the lower the temperature of the tank, its temperature decreases with increasing temperature. Thus, it saves electricity and never burns out, even with self-intersection. The self-regulation property allows the creation of safe tank heating systems.

Reservoir cabel heating

- Heating cables and accessories for reservoirs.

- Switching boxes and fasteners.

- Control systems: control boxes, thermostats, launch and protect equipments.

ENGL electric heating flexible tapes for heating tanks, containers and cisterns

ENGL electric heating tapes have proven to be excellent itself in tank and tank heating systems, becoming the best alternative to heating cable. The fact that the tapes are produced on the territory of the Russian Federation with the use of domestic components adds to the relevance in the choice of ENGL tapes.

ENGL electric heating tapes have proven to be excellent itself in tank and tank heating systems, becoming the best alternative to heating cable. The fact that the tapes are produced on the territory of the Russian Federation with the use of domestic components adds to the relevance in the choice of ENGL tapes.

5 Reasons to Choose Electric Flexible Band Heaters

The "ENGL" tapes of any type, power and length presented on the Online Energy website have incorporated five key indicators, the most significant for both small commercial organizations and large industrial companies during the period of solving the issue of heating various equipment or areas:

- Affordable price when buying "ENGL".

- Simplicity and high speed in the implementation of installation work

- Effective heating.

- Durability of electric heaters "ENGL".

- Production in Russia.

The structure and principle of operation of the ENGL electric heating tape

Flexible tape heaters "ENGL" are heaters made of flexible glass fiber, the main for which are eight heating wires made of nichrome. The outer shell is made of silicone rubber, due to which, it becomes waterproof. The end crimps are also watertight as they are made from the same silicone rubber.

Design features and functionality of ENGL heating tapes

The ends of the ENGL heating tape are pressed in production, so the tapes are manufactured in fixed sizes and capacities. Due to the elasticity and appropriate shape of the tapes, it is possible to use ENGL heating tapes for heating complex shapes in hard-to-reach places and under difficult conditions, for example, in pipelines. It should be noted that ENGL heating tapes are ideal for use in conjunction with a thermostat in order to achieve optimal temperature conditions, prevent overheating and save energy.

Favorable cost of the ENGL heating system

The cost of elastic flexible tape heaters is often several times lower than the closest analogues. Due to the selection of "ENGL" models with characteristics that suit your requirements, the customer receives a tape with the parameters set by the manufacturer (length, rated power, power density), which allows saving without buying an "extra" length.

Easy to install

Due to the flexibility of the material and the length precisely matched to the object, the elastic flexible band heater can be mounted quickly and easily. "ENGL" does not require any special skills and tools.

Fast and efficient heating

Elastic flexible band heaters have high thermal conductivity and power density. Therefore, when using the above materials, there is a quick warm-up and maintenance of the necessary heat using thermostats.

Fields of application for flexible tape heaters ENGL

- Frost protection in pipes.

- Short-term heating of machinery and equipment (e.g. engines).

- Integrated heating elements.

- Viscosity control while moving through the pipe

- Heating of laboratory equipment.

- Maintaining the required temperature in control panels.

- Heating plastics.

- Corrosion control in silos

- External heating of tools and fixtures.

- Short-term heating

- Valve and valve heating

Types of ENGL heating tapes presented on the site Online Energy

- ENGL-1 electric heating tape.

ENGL-1 heaters can be used in fire hazardous installations (outdoors and indoors) of classes П-I; P-II; P-III according to the classification of the "Electrical Installation Rules" (PEU). ENGL-1 is a braided glass fiber tape based on eight nichrome heating cores. Outside, the heaters are covered with a waterproof sheath made of silicone rubber. Silicone rubber insulation is particularly suitable for applications where high tape flexibility is required. Tapes "ENGL-1" are finished products, produced only in certain sizes and capacities, and are not subject to cutting in place. Under the order, it is possible to manufacture a heating tape with other parameters and lengths, but with a specific power not exceeding 100 W/m.

ENGL-1 heaters can be used in fire hazardous installations (outdoors and indoors) of classes П-I; P-II; P-III according to the classification of the "Electrical Installation Rules" (PEU). ENGL-1 is a braided glass fiber tape based on eight nichrome heating cores. Outside, the heaters are covered with a waterproof sheath made of silicone rubber. Silicone rubber insulation is particularly suitable for applications where high tape flexibility is required. Tapes "ENGL-1" are finished products, produced only in certain sizes and capacities, and are not subject to cutting in place. Under the order, it is possible to manufacture a heating tape with other parameters and lengths, but with a specific power not exceeding 100 W/m. - ENGL-2 electric flexible band heater.

"ENGL-2" is flexible heating tape of industrial quality, which can be used for process heating or maintenance of pre-set temperatures up to 60 0C. Due to its high flexibility, ENGL-2 is ideal for short-term heating of equipment and machinery (for example, engines).Elastic pipe heating tape is used to protect against freezing, compensate for heat losses or process heating of pipelines and tanks, heat exchangers, tanks, devices, valves, control equipment and other equipment. Operation of heaters is allowed in fire-hazardous installations (outdoors and indoors) of classes P-I, P-II, P-III, in accordance with the "Electrical Installation Rules" (PUE). "ENGL-2" is a braided tape made of glass fiber, based on eight heating wires made of nichrome. Outside, the heaters are covered with a waterproof sheath made of a polyethylene composition. End crimps are made of the same material. The principle of operation of the ENGL-2 heaters is based on the release of heat by the heating conductors when an electric current passes through them. The tape is a finished product, available only in the specified sizes and capacities and cannot be cut to size. By agreement with the buyer, it is possible to manufacture heaters with other parameters and lengths, but with a specific power not exceeding 40 W/m.

"ENGL-2" is flexible heating tape of industrial quality, which can be used for process heating or maintenance of pre-set temperatures up to 60 0C. Due to its high flexibility, ENGL-2 is ideal for short-term heating of equipment and machinery (for example, engines).Elastic pipe heating tape is used to protect against freezing, compensate for heat losses or process heating of pipelines and tanks, heat exchangers, tanks, devices, valves, control equipment and other equipment. Operation of heaters is allowed in fire-hazardous installations (outdoors and indoors) of classes P-I, P-II, P-III, in accordance with the "Electrical Installation Rules" (PUE). "ENGL-2" is a braided tape made of glass fiber, based on eight heating wires made of nichrome. Outside, the heaters are covered with a waterproof sheath made of a polyethylene composition. End crimps are made of the same material. The principle of operation of the ENGL-2 heaters is based on the release of heat by the heating conductors when an electric current passes through them. The tape is a finished product, available only in the specified sizes and capacities and cannot be cut to size. By agreement with the buyer, it is possible to manufacture heaters with other parameters and lengths, but with a specific power not exceeding 40 W/m. - ENGLU-400 flexible tape electric heater.

"ENGLU-400" a glass fiber tape impregnated with an organic silicate material.It is based on eight heating wires made of an alloy with high resistivity (nichrome). The heating wire winding consists of three layers of impregnated glass fiber. The connection of the heating elements of the tape heater is made by the method of micro-plasma welding. Depending on the connection scheme, the heating tape "ENGLU-400" has different capacities and lengths. The low-temperature terminals are placed in switching lugs, the internal cavities of which are filled with a heat-resistant electrical insulating compound during assembly. Tape heater "ENGLU-400" is designed to compensate for heat losses and heating of pipelines, heat exchangers and other process equipment. Besides, the tape heater can be used for heating of small rooms, garages, greenhouses, containers. During operation in the heating mode, it is advisable for the consumer to use the heater at full power, and then switch it to reduced power. When buying such a tape element for active heating systems, it is necessary to take into account the type of connection (one-sided or two-sided) and the required cable length. It is possible to manufacture a tape heater according to an individual order, personal parameters. Mounting where overlapping, kinking or twisting of the cable heater is not allowed. Before connecting, it is required to study the principles of operation of the systems and electrical equipment being created, as well as safety rules.Unused free ends of the heater tape must be insulated to eliminate the risk of short circuit and electric shock.

"ENGLU-400" a glass fiber tape impregnated with an organic silicate material.It is based on eight heating wires made of an alloy with high resistivity (nichrome). The heating wire winding consists of three layers of impregnated glass fiber. The connection of the heating elements of the tape heater is made by the method of micro-plasma welding. Depending on the connection scheme, the heating tape "ENGLU-400" has different capacities and lengths. The low-temperature terminals are placed in switching lugs, the internal cavities of which are filled with a heat-resistant electrical insulating compound during assembly. Tape heater "ENGLU-400" is designed to compensate for heat losses and heating of pipelines, heat exchangers and other process equipment. Besides, the tape heater can be used for heating of small rooms, garages, greenhouses, containers. During operation in the heating mode, it is advisable for the consumer to use the heater at full power, and then switch it to reduced power. When buying such a tape element for active heating systems, it is necessary to take into account the type of connection (one-sided or two-sided) and the required cable length. It is possible to manufacture a tape heater according to an individual order, personal parameters. Mounting where overlapping, kinking or twisting of the cable heater is not allowed. Before connecting, it is required to study the principles of operation of the systems and electrical equipment being created, as well as safety rules.Unused free ends of the heater tape must be insulated to eliminate the risk of short circuit and electric shock.

-

High temperatures may be required for:

- Construction industry: bitumen / asphalt heating.

- Paint industry: curing ovens

- Chemical industry: injection molding machines, extruders.

- Metalworking: light alloy melting

- Heating of press plates, dies, molds, equipment of contact and convective heating devices, including drying and oven ovens.

- ENGLEx-1 flexible band electric heater.

"ENGLEx-1" » is an industrial-quality electric heating tape for freezing protection or maintaining the set temperature of pipelines and tanks, shut-off valves, control equipment, etc., including in hazardous areas. "ENGLEx-1" is a woven glass fiber tape, based on eight heating conductors made of nichrome. Outside, the heaters are covered with a waterproof sheath made of silicone rubber. End crimps are made of the same rubber. Silicone rubber insulation is particularly suitable for applications where high tape flexibility is required. The heater has a continuous protective braid of copper wire. "ENGLEx-1" heaters are supplied as ready-made heating sections with "cold ends". If it is not possible to use standard sections, delivery is carried out according to an individual project or order.

"ENGLEx-1" » is an industrial-quality electric heating tape for freezing protection or maintaining the set temperature of pipelines and tanks, shut-off valves, control equipment, etc., including in hazardous areas. "ENGLEx-1" is a woven glass fiber tape, based on eight heating conductors made of nichrome. Outside, the heaters are covered with a waterproof sheath made of silicone rubber. End crimps are made of the same rubber. Silicone rubber insulation is particularly suitable for applications where high tape flexibility is required. The heater has a continuous protective braid of copper wire. "ENGLEx-1" heaters are supplied as ready-made heating sections with "cold ends". If it is not possible to use standard sections, delivery is carried out according to an individual project or order.

Explosion-proof flexible cable heating elements "ENGKEx-1" have improved characteristics and are designed to heat up and compensate for heat losses of various process equipment, apparatus, pipelines, valves, control equipment, etc., including those in hazardous areas classified according to the classification "Electrical Installation Rules" (PUE) to class B-Ia, B-Ib, B-Ig, where explosive mixtures of gases and vapors with air of categories IIA, IIB, IIC and groups T1, T2, T3, T4, T5 and T6, in accordance with GOST 12.1.011-78. According to its design, the ENGKEx-1 hea From the characteristics of the heating cable type "ENGKEh-1" can be noted the ability to withstand high temperatures. But at the same time, it is necessary to control the maximum permissible temperatures that the materials from which the cable is made can withstand. Overheating can be prevented by using temperature control, lowering the temperature of the pipeline, and design calculations.

Explosion-proof flexible cable heating elements "ENGKEx-1" have improved characteristics and are designed to heat up and compensate for heat losses of various process equipment, apparatus, pipelines, valves, control equipment, etc., including those in hazardous areas classified according to the classification "Electrical Installation Rules" (PUE) to class B-Ia, B-Ib, B-Ig, where explosive mixtures of gases and vapors with air of categories IIA, IIB, IIC and groups T1, T2, T3, T4, T5 and T6, in accordance with GOST 12.1.011-78. According to its design, the ENGKEx-1 hea From the characteristics of the heating cable type "ENGKEh-1" can be noted the ability to withstand high temperatures. But at the same time, it is necessary to control the maximum permissible temperatures that the materials from which the cable is made can withstand. Overheating can be prevented by using temperature control, lowering the temperature of the pipeline, and design calculations.- Switching lugs.

- Heating (active) part.

- Low temperature outlets

Proposed heating and antifreeze systems for pipes, water pipes (pipe heaters)

The cable and tape heating system "Antifreeze and heating of pipes" (pipe heater) is used to protect against freezing and maintain the set temperature of such objects as:

- Pipelines (water pipes, etc.).

- Indoor pipes.

- Pipes in the street, both above ground and underground.

- Drainage pipes.

- Sewerage.

- Fire lines and hydrants

Composition of a cable or tape heating system for pipelines

Depending on the specific heating task, size and other characteristics of the system, the layout of the heating system can be more or less complex. Extended and branched systems include a large number of sensors, couplings, regulators and mounting boxes.

Pipeline heating system includes:

- Heating part: heating cables, heating tapes and accessories for their fastening on the pipeline, local elements for heating pipeline units (flanges, valves, pumps).

- Distribution network that provides power to all elements of the heating part and conducts information signals from sensors to the control system panel: power and information cables, heating tapes, junction boxes and fasteners.

- Control system: control cabinets, thermostats, pipe and air temperature sensors, flow sensors, ballasts and protection equipment.

Parameters of a cable or tape heating system for pipelines

The parameters depend on:

- properties of the transported product (maximum product temperature, pipeline inlet temperature, pour point, solids settling temperature);

- pipe characteristics (material, geometric dimensions, thermal insulation, open or underground location);

- piping topologies (linear, branched, with few or many sections);

- environment characteristics (minimum and maximum ambient temperatures, wind speed).

Based on these data, the following are determined:

- calculated value of the maximum heat loss of the pipeline.

- type of heating cable or heating tape (there may be different cables or tapes in one system), their length and location on the pipe (number of threads, pitch).

- type of accessories for powering sections (junction boxes, terminations, couplings).

- structure and parameters of the distribution network (or lack thereof).

- structure and parameters of the control system (thermostats and switching devices, control cabinets, transformers).

Since oil and oil products transportation systems are explosive and fire hazardous objects, only explosion-proof components (heating cables, heating tapes, temperature controllers, mounting and distribution boxes) are used in heat heating systems. They are also adapted for operation in conditions of high humidity, in aggressive environments, for laying underground or underwater pipelines.