Heated high pressure hoses

Our company Online Energy is a leading supplier of heated hoses and flexible heating cables. Depending on the purpose and area of application, flexible heated lines presented on the site provide transportation of liquid and gaseous media without losing their temperature.

Applications for Heated High Pressure Hoses

• Gas analysis, where fixedly routed heated hoses take samples of flue gases, for example from a chimney, and deliver them to the analyzer.

• Gas analysis, where fixedly routed heated hoses take samples of flue gases, for example from a chimney, and deliver them to the analyzer.

• Gas analysis, portable measurement systems, eg for sampling in the field.

• Use in industry - mechanical engineering and plant assembly.

• Chemical and petrochemical industry.

• Food industry.

• Automotive industry, eg gluing of body parts with moving parts of installations (robots).

As a rule, frost protection and operating temperatures up to 450 °C can be implemented without problems with standard equipment.

Specifications for high pressure hoses

| Analytical instrumentation | |

| Holding temperature / frost protection | 5 to 450 °C |

| Conditional pass | 4 -10 mm |

| Industrial Applications/Pressure Hoses | |

| Holding temperature / frost protection | 5 to 250 °C |

| Conditional pass | 8-100 mm |

All heated hoses are designed and manufactured to order. We also offer flexible heated pipelines that can be used in hazardous areas.

Heated adjustable pressure hoses ELH/MD, HD,SHD

Heated pressure hoses are used for heating, maintaining a constant temperature and transporting the following substances without reducing their temperature: oils, lubricants, wax, resin, tar, paints, water, adhesives, plastics, casting compounds, foodstuffs, etc. .d. In this case, heated hoses are mainly mounted on moving parts of machines and installations. Temperature range: up to 250 °C as standard.

Heated pressure hoses are used for heating, maintaining a constant temperature and transporting the following substances without reducing their temperature: oils, lubricants, wax, resin, tar, paints, water, adhesives, plastics, casting compounds, foodstuffs, etc. .d. In this case, heated hoses are mainly mounted on moving parts of machines and installations. Temperature range: up to 250 °C as standard.

Benefits of Eltherm pressure hoses

- Operating temperature: 5 - 250 °C as standard.

- Nominal bore: 4 - 25 mm as standard.

- Voltage: 12 - 400 V

- Operating pressure: up to 500 bar.

- The heat load values are optimized depending on the purpose of use.

- Possibility of delivery for the automotive industry in a version without the use of silicone.

Application specifics

- The transported substance remains fluid only at a certain temperature.

- The transported substance retains its specific processing properties only within a certain temperature range.

- The substance to be transported can only be handled at a certain temperature.

- The heated hose must be portable or flexible due to the moving parts of the equipment attached to it.

Application examples for high pressure hoses

- Connecting equipment/hot gluing plants, packaging, gluing and labeling machines.

- Surface finishing/dosing and painting units.

- Food industry, bottling plants.

- Foam extinguishing systems, polyurethane foam machines, roof repairs, packaging machines.

- Installations working with epoxy resins.

- Washing plants, steam cleaners, pipe cleaning.

- Loading and elevator hoses

- Dosing plants.

- Glass industry for coating and bonding thermal glass sheets.

- Gluing robots.

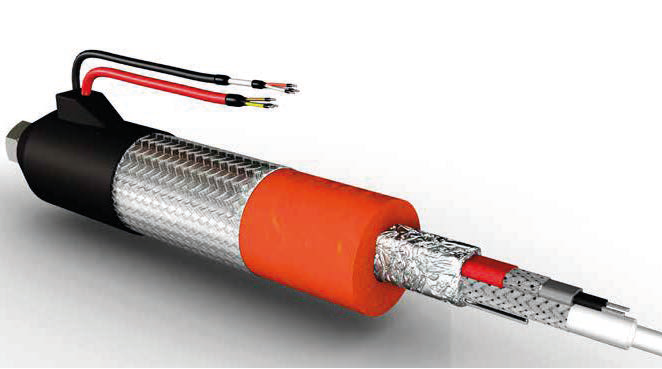

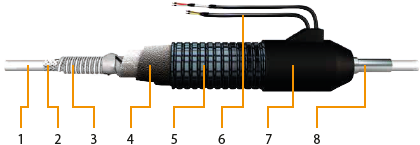

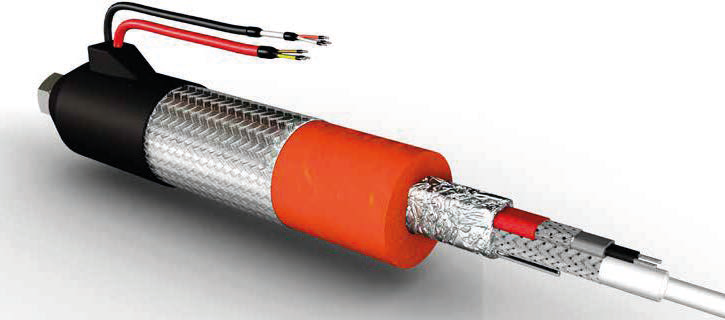

Construction of Eltherm Heated High Pressure Hoses

1. Internal ducts. The choice of internal duct depends on the maximum operating pressure, maximum operating temperature and the respective application.

1. Internal ducts. The choice of internal duct depends on the maximum operating pressure, maximum operating temperature and the respective application.

2. Sensor. A temperature sensor is installed between the inner duct and the heating cable to carry out the adjustment. Additional sensors can be installed on either side for additional temperature measurement. Typically PT-100 sensors are used in standard 2-wire cables.

3. Heating cable. Resistive heating cable used as a base element. For this purpose, only heating cables with PTFE or perfluorinated copolymer insulation are used. In addition, great importance is attached to achieving the highest possible power density, resulting in even heat distribution. For temperatures up to 250 °C, as a rule, we use the heating cable "ELKM-AE" or for strong dynamic loads - "ELKM-AG". Spacer: The braided fiberglass spacer reliably protects the heating cable from mechanical damage and hot spots when bent.

4. Insulation. The insulation depends on the maximum operating temperature as well as the choice of outer jacket (see hose designs page). Special types of non-woven thermofibres are mainly used, as well as foam hoses (up to 100 °C elastomer hose, up to 250 °C silicone hoses).

5. Outer jacket. Application, bending radius and ambient temperature determine the choice of outer jacket. The outer casing protects the heated hose from moisture, atmospheric factors, mechanical and dynamic loads (for example, on a robot).

6. Connection cable As standard, the sensor cable and connection cable are led out separately. The standard length of the connection cable is 1.5 m. Any standard plug can be connected to the connection cable if desired.

7. End caps. End caps terminate the heated hose at both ends. An integrated strain relief ensures that the connecting cable is safely relieved. Standard end caps are available in silicone, EPDM, polymer (polyamide) and galvanized metal.

8. Connecting fittings. Connection of the heated hose to the installation part (container, nozzle, etc.).

Heated high pressure pressure hoses with multiple heated inner passages

Heated pressure hoses with multiple heated internal passages are widely used where it is necessary to transport two or more materials without loss of temperature.

Heated pressure hoses with multiple heated internal passages are widely used where it is necessary to transport two or more materials without loss of temperature.

For example, dosing systems, two-component plants, coating and surface treatment plants, PU foam extinguishing systems, epoxy resin plants, etc. The temperature range in the standard version does not exceed 200°C.

Benefits of Eltherm and high pressure pressure hoses with multiple heated internal passages

- All internal channels can be heated together in one heated hose.

- This saves costs and minimizes installation costs.

- Compact design.

- Nominal bore: 4 - 20 mm.

- Heat load values are optimized according to the purpose of use.

- Possibility of delivery for the automotive industry in silicone-free version.

Application specifics

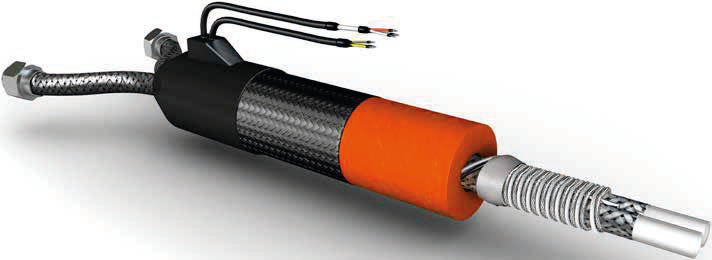

The design of pressure hoses Eltherm with several internal channels

1. Internal ducts. The choice of internal duct depends on the maximum operating pressure, maximum operating temperature and the respective application.

1. Internal ducts. The choice of internal duct depends on the maximum operating pressure, maximum operating temperature and the respective application.2. Sensor. A temperature sensor is installed between the inner duct and the heating cable to carry out the adjustment. Additional sensors can be installed on either side for additional temperature measurement. Typically PT-100 sensors are used in standard 2-wire cables.

3. Heating cable. Resistive heating cable used as base element Only PTFE or perfluorinated copolymer insulated heating cables are used for this purpose. In addition, great importance is attached to achieving the highest possible power density, resulting in even heat distribution. For temperatures up to 250 °C, the "ELKM-AE" heating cable is usually used, or for high dynamic loads, the "ELKM-AG" heating cable. Spacer: The fiberglass braided spacer reliably protects the heating cable from mechanical damage and spot overheating when bent.

4. Insulation. The insulation depends on the maximum operating temperature as well as the choice of outer casing. Special types of non-woven thermofibres are mainly used, as well as foam hoses (up to 100 °C elastomer hose, up to 250 °C silicone hoses).

5. Outer jacket. Application, bending radius and ambient temperature determine the choice of outer jacket. The outer casing protects the heated hose from moisture, atmospheric factors, mechanical and dynamic loads (for example, on a robot).

6. Connection cable. As standard, the sensor cable and connection cable are led out separately. The standard length of the connection cable is 1.5 m. Any standard plug can be connected to the connection cable if desired.

7. End caps. End caps terminate the heated hose at both ends. An integrated strain relief ensures that the connecting cable is safely relieved. Standard end caps are available in silicone, EPDM, polymer (polyamide) and galvanized metal.

8. Connecting fittings. Connection of the heated hose to the installation part (container, nozzle, etc.).

Heated high pressure pressure hoses with self-regulating heating cable

Self-regulating pressure hoses are widely used where materials need to be transported in flexible pipes at temperatures up to 100°C. They are ideally suited in cases where only the temperature of the conveyed substances is required and the process does not require any heating phases. Due to their self-adjusting properties, they are not suitable for all applications. These pressure hoses cannot be used in combination with robots as they are not suitable for quick change of bending load.

Self-regulating pressure hoses are widely used where materials need to be transported in flexible pipes at temperatures up to 100°C. They are ideally suited in cases where only the temperature of the conveyed substances is required and the process does not require any heating phases. Due to their self-adjusting properties, they are not suitable for all applications. These pressure hoses cannot be used in combination with robots as they are not suitable for quick change of bending load.

Temperature maintenance: up to 100 °C as standard.

Application specifics

- The substance to be transported must be protected from freezing.

- Due to technological reasons, the temperature of the transported substance must not fall below a certain value.

- Installation geometry requires pipeline flexibility.

- Frost protection for fuel lines.

- Freeze protection for hydraulic lines.

- General temperature maintenance in mechanical engineering.

Advantages

- Operating temperature: 5-100 °C.

- Nominal diameter DN4-DN25.

- Power varies depending on ambient temperature.

- Self-adjusting power/regulator is not necessary.

- Heating cable of own production.

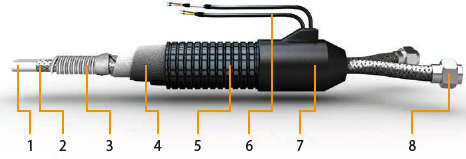

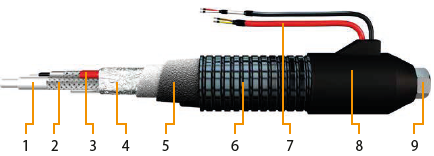

Construction of high pressure pressure hoses with self-regulating heating cable

1. Internal channels.

1. Internal channels.

2. Sensor. For precise temperature control, a temperature sensor can optionally be installed between the inner duct and the heated cable. Additional sensors can be installed on either side for additional temperature measurement. Typically PT-100 sensors are used in standard 2-wire cables.

3. Self-regulating heating cable. Self-regulating heating cable. Heating cables consist of two parallel copper wires inserted into a vulcanized polymer heating element with an admixture of carbon particles. If the temperature rises during operation, the polymer expands at the molecular level, and the distance between the carbon particles increases. The resistance rises and the power drops. Cooling reverses this process and the power increases.

4. Aluminum foil. For better heat distribution.

5. Insulation. The insulation depends on the maximum operating temperature as well as the choice of outer jacket (see Hose Designs). Special types of thermal non-woven fabrics are mainly used, as well as foam hoses (up to 100 °C elastomer hose, up to 250 °C silicone hoses).

6. Connection cable. In the standard version, the connection cable is terminated separately (sensor cable and sensor cable). The standard length of the connection cable is 1.5 m. Any standard plug can be connected to the connection cable if desired.

7. Outer jacket. Application, bending radius and ambient temperature determine the choice of outer jacket. The outer casing reliably protects the heated hose from moisture, atmospheric factors, and mechanical stress.

8. End caps. End caps terminate the heated hose at both ends. An integrated strain relief ensures that the connecting cable is safely relieved. Standard end caps are available in silicone, EPDM, polymer (polyamide) and galvanized metal.

9. Connecting fittings. Connection to analyzer or probe.