Rail, Track and Switch Point Heating Eltherm

The operators of public and private commuter and freight railway networks require smooth, safe traffic, wherever winters are cold with frequent ice and snow. Freeze prevention on tracks and switch points to keep them free from ice keeps trains safely on track and on time. A reliable, energy efficient electrical trace heating system with intelligent control achieves just that and assures you of several technical and economic advantages:

The operators of public and private commuter and freight railway networks require smooth, safe traffic, wherever winters are cold with frequent ice and snow. Freeze prevention on tracks and switch points to keep them free from ice keeps trains safely on track and on time. A reliable, energy efficient electrical trace heating system with intelligent control achieves just that and assures you of several technical and economic advantages:

Advantages

- Optimised heat transfer from the trace heater to the railway track or switch point

- Best possible energy efficiency and cost saving operation

- Simple, fast assembly for quick installation and easy maintenance

- Low maintenance effor

- Prevention of damages or short-circuits through moisture thanks to fluoropolymer insulation

- Easy access to the trace heater thanks to attachment to the outside of the rail or switch point

- Protection and prevention of heat loss thanks to thermally insulating cover profile

Applications

- Freeze prevention

- Railway

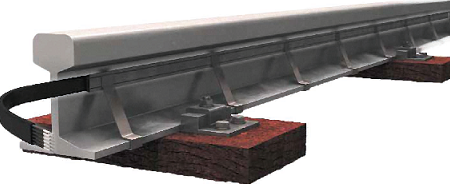

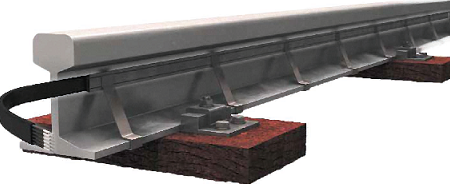

System design

- El-Rail: 6 series resistance trace heaters, fluoropolymer insulated and embedded in silicone jacket plus thermally insulating cover profile and holding bracket for freeze prevention on railway tracks.

- El-Point: Parallel resistance trace heater with constant wattage (W/ft) power output, fluoropolymer insulation and thermally insulating cover profile and holding bracket for freeze prevention on switch points.

- El-Track: Parallel resistance trace heater with constant wattage (W/ft) power output, fluoropolymer insulation and thermally insulating cover profile and fast assembly clip for freeze prevention on power rails.

EL-Rail up to 150 °C

Benefits

- Lowest possible number of power supply points

- Continuous heat transfer

- Resistant to moisture

- Additional protection against aggressive substances

- Suited for stock rails, switch points and power rails

- Robust design

- Optimised heat transfer

- Fast, simple assembly

- Low maintenance effort

Technical information

|

Maximum ambient temperature, power on

|

50 °C

|

|

Maximum ambient temperature, power on

|

150 °C

|

|

Maximum nominal voltage

|

1000 V

|

|

Minimum bending radius

|

2“ / 50 mm

|

|

Power output

|

50 - 150 W/m

|

|

Dimensions

|

8 x 34 mm

|

|

Minimum installation temperature

|

– 40 °C

|

EL-Point up to 200 °C

Constuction of EL-Point

- Bus wire

- Core - silicone

- Insulation - Fluoropolymer

- Protective braid - Cu, nickel plated

- Outer jacket - Fluoropolymer

Applications

- Freeze prevention

- Switch points

Benefits

- High power output

- Optimised heat transfer

- Efficient, energy saving

- Moisture proof

- Suited for all switch points

- No interference with signal devices

- Robust design

- Optimised heat transfer

- Fast, simple assembly

- Low maintenance effort

- Simplified storage and handling of spare parts

- Can be cut to size

Technical information of EL-Point

|

Maximum ambient temperature, power on

|

50 °C

|

|

Maximum ambient temperature, power on

|

200 °C

|

|

Maximum nominal voltage

|

750 V

|

|

Minimum bending radius

|

50 mm

|

|

Power output

|

50 - 150 W/m

|

|

Dimensions

|

15 x 7 mm

|

|

Minimum installation temperature

|

– 50 °C

|

The operators of public and private commuter and freight railway networks require smooth, safe traffic, wherever winters are cold with frequent ice and snow. Freeze prevention on tracks and switch points to keep them free from ice keeps trains safely on track and on time. A reliable, energy efficient electrical trace heating system with intelligent control achieves just that and assures you of several technical and economic advantages:

The operators of public and private commuter and freight railway networks require smooth, safe traffic, wherever winters are cold with frequent ice and snow. Freeze prevention on tracks and switch points to keep them free from ice keeps trains safely on track and on time. A reliable, energy efficient electrical trace heating system with intelligent control achieves just that and assures you of several technical and economic advantages: