SRF(S) 16-2-CR

Specialized heating cable for heating drinking water pipes Fine Korea SRF(S) 16-2CR

The "SRF(S)16-2-CR" cable from Online Energy is a self-regulating, positive temperature coefficient, low power consumption, tinned copper braided cable. Designed for insertion into pipes where there is no other way to protect the pipe from freezing. The maximum short-term exposure temperature is 85 ºС. Temperature rating - T6.

Specialized heating cable for heating pipes with drinking water. The cable is based on a self-regulating heating cable using modern materials and technologies developed for the food industry. The cable has a certificate of conformity. Self-regulating heating cable is designed for heating pipelines in winter. The use of a cable for heating pipes and pipelines with drinking water, allows you to reduce the depth of laying pipeline. If the pipeline has already been laid, at a shallow depth, it eliminates the likelihood of freezing and destruction in the winter. Installation of the heating cable, inside the pipe, is possible on the finished and commissioned pipe.

Specialized heating cable for heating pipes with drinking water. The cable is based on a self-regulating heating cable using modern materials and technologies developed for the food industry. The cable has a certificate of conformity. Self-regulating heating cable is designed for heating pipelines in winter. The use of a cable for heating pipes and pipelines with drinking water, allows you to reduce the depth of laying pipeline. If the pipeline has already been laid, at a shallow depth, it eliminates the likelihood of freezing and destruction in the winter. Installation of the heating cable, inside the pipe, is possible on the finished and commissioned pipe.

The "SRF" series cables, using the PTC principle, regulate their own output power depending on the ambient temperature under the influence of the current flowing through the cable core, and reduce power consumption during operation.

Unlike conventional metal wire, which generates heat based on its length, the core of a cable is made up of endless parallel bonds of carbon particles. Parallel connections allow you to cut the cable to the exact length without waste.

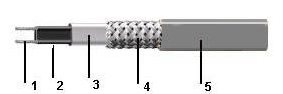

Design of Fine Korea SRF(S)-16-2-CR heating cable from Online Energy

1. Copper bar.

1. Copper bar.

2. Self-regulating conductive core.

3. Modified polyolefin insulation.

4. Tinned copper braid (CR).

5. Fluoroplastic external thermal insulation (CT).

Parameters of FineKorea SRF(S)-16-2-CR heating cable

- Long service life (semi-permanent). During the manufacturing process, the cable is additionally treated at elevated temperature with intermediate annealing to give it stability without loss of thermal output during its entire service life.

- Low power consumption. The low power consumption of the cable is due to its unique positive temperature coefficient (PTC).

- Excellent temperature resistance. During the manufacturing process, the cable is cross-linked and vulcanized to provide the same thermosetting properties as XLPE (cross-linked molecular structure).

- Cut to desired length. The core of the cable consists of endless parallel bonds of carbon particles, which allows the cable to be cut into pieces of the exact required length.

Residual current circuit breaker current dependence and maximum circuit length

220 V| Start temperature | ||||

|---|---|---|---|---|

| 15 A | 20A | 30A | 40 A | |

| 10 0C | 85 | 100 | - | - |

| 0 0C | 80 | 95 | 100 | - |

| - 200C | 90 | 75 | 90 | 100 |

| - 400C | fifty | 65 | 80 | 90 |