Ruffneck

Heaters for the harsheat environments Ruffneck

Ruffneck from Thermon Heating Systems Inc. is renowned for its rugged, reliable and versatile heavy-duty explosion-proof heaters, heating systems and heating accessories. Ruffneck has a long and proud history of supplying quality heating products for the harshest industrial environments to a worldwide customer base for over 30 years. The Ruffneck line has enhanced Thermon Heating System’s position as one of North America’s leading manufacturers of industrial heating equipment.

Ruffneck from Thermon Heating Systems Inc. is renowned for its rugged, reliable and versatile heavy-duty explosion-proof heaters, heating systems and heating accessories. Ruffneck has a long and proud history of supplying quality heating products for the harshest industrial environments to a worldwide customer base for over 30 years. The Ruffneck line has enhanced Thermon Heating System’s position as one of North America’s leading manufacturers of industrial heating equipment.

Ruffneck is well-known in the industry for its “ship the heat in a week” policy, where 95% of all standard orders are shipped within one week of order placement.

Thermon Heating Systems Inc. is a world leader in the development and production of advanced heating and filtration solutions for industrial and hazardous area applications.

Types of Ruffneck

- Explosion-Proof Electric Unit Heaters.

- Explosion-Proof Convection Heaters.

- Heat Exchanger Unit Heaters.

- Washdown Unit Heaters.

- Forced Air Unit Heaters.

- Duct Heaters.

- Explosion-Proof Exhaust Fans.

- Accessories.

Explosion-Proof ELectric Unit Heaters

FX5 Explosion-Proof Electric Air Unit Heaters

Designed for the harshest environments. For use in dry indoor industrial applications with hazardous environments where explosive gases or dusts may be present.

Designed for the harshest environments. For use in dry indoor industrial applications with hazardous environments where explosive gases or dusts may be present.• The heater core assembly is contained in a sturdy, epoxy-coated, 12-gauge steel cabinet.

• Utilizes the VacuCore® liquid-to-air heat exchanger, which provides high efficiency, fast warm-up and even heat distribution across the face of the exchanger.

• Optional Heresite® coating and stainless steel construction for corrosive environments available.

• Models offered in 3 – 35 kW, ranging from 208 – 600V.

• UL certified and approved for the following Hazardous Locations: Class I, Division 1 & 2, Groups C & D; Class II, Division 1, Groups E, F & G; Class II, Division 2, Group F & G, Class I, Zones 1 & 2, Groups IIA & IIB; Temperature Code T3B.

• Available slim or regular control enclosure.

• Available FX5-SD Severe Duty option.

FE2 Explosion-Proof Electric Air Unit Heaters

European variant of the FX5, adapted to 50 Hz power and registered to European standards.

European variant of the FX5, adapted to 50 Hz power and registered to European standards.• Utilizes the VacuCore® liquid-to-air heat exchanger, which provides high efficiency, fast warm-up and even heat distribution across the face of the exchanger.

• Optional Heresite® coating and stainless steel construction for corrosive environments available.

• Models offered in 2.5 – 23.1 kW, ranging from 220 – 440V, 50 Hz.

• CE/ATEX II 2 G, Ex d IIB T3 Gb and EAC approved for global markets.

• - 50°C EAC certification available.

Explosion-Proof Convection Heaters

CX1 Provector Explosion-Proof Convection Heaters

Designed and manufactured specifically for hazardous locations and harsh operating conditions, such as those in the oil and gas industry.

Designed and manufactured specifically for hazardous locations and harsh operating conditions, such as those in the oil and gas industry.• Sloped-top cabinet prevents objects that restrict airflow from being set on top.

• Models offered in 0.75 – 10.0 kW, ranging from 120 – 600V, single phase, and 208 – 600V three phase.

• ULUS listed approvals for Class I, Divisions 1 & 2, Groups A, B, C, D; Class I, Zones 1 & 2, Groups IIA, IIB and IIC

CF1 Provector® Explosion-Proof Convection Heaters

European variant of the CX1, adapted to 50 Hz power and registered to European standards.• Sloped top cabinet prevents objects that restrict ai+rflow from being set on top.

• Models offered in 0.25 – 7.6 kW, ranging from 220 – 415V, single phase

• CE/ATEX and IEC Ex, II 2 G Ex d IIB/IIC T2, T3 or T4 Gb and EAC approved for global markets.

Heat Exchanger Unit Heaters

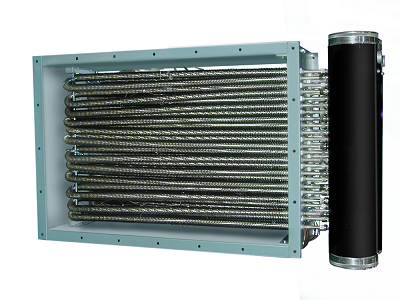

FR Heat Exchanger Unit Heaters

Designed for steam applications that may be subject to freezing conditions.

Designed for steam applications that may be subject to freezing conditions.• Heat exchanger cores are of steel construction with tension wound, close fitting aluminum fins.

• Maximum operating pressures up to 200 psi.

• Motors ranging from 115 – 575V, with the option of TEFC or explosion-proof.

• Canadian CRN approved.

• CSA and EAC approved heaters available.

• Certified built-in disconnect available.

HP Heat Exchanger Unit Heaters

Designed for rugged industrial applications including space heating and liquid cooling applications.

Designed for rugged industrial applications including space heating and liquid cooling applications.• These high pressure heaters are suitable for a wide range of heating fluids including steam, glycol/water mixture, TEG, etc.

• Maximum operating pressures up to 450 psi and maximum operating temperature of 650°F (343°C).

• Motors ranging from 115 – 575V, with the option of TEFC or explosion-proof.

• Canadian CRN approved.

• CSA and EAC approved heaters available.

• Certified built-in disconnect available.

AH/AV Unit Heaters

Designed for rugged industrial applications and can be used with a variety of heat transfer fluids such as steam, circulating hot water, and glycol heating systems, or in liquid cooling applications.• These high pressure heaters are suitable for a wide range of heating fluids including steam, glycol/water mixture, TEG, etc.

• Maximum operating pressure of 525 psi and maximum operating temperature of 650°F (343°C).

• Models from 6,000 – 1,200,000 Btu/hr.

• Motors ranging from 115 – 575V, with the option of TEFC or explosion-proof.

• Canadian CRN approved.

• CSA approved heaters available.

• Certified built-in disconnect available.

Washdown Unit Heaters

CR1 Triton Corrosion-Resistant Washdown Heaters

Designed for non-hazardous industrial locations with elevated moisture levels.

Designed for non-hazardous industrial locations with elevated moisture levels.• NEMA Type 4X construction for increased safety and protection against water penetration.

• Epoxy-coated fan blade and 16 gauge stainless steel cabinet for increased corrosion resistance.

• 37 models offered in 13 – 39 kW, ranging from 208 – 600V.

• Custom configured stainless steel spiral-finned heating elements for improved heat distribution and corrosion protection.

• UL listed Type 4X for coast guard and marine applications.

• Suitable for wash bays and humid locations.

• Able to withstand water spray of up to 70 PSIG (483 kPa).

• CSAUS and EAC approved.

CRE1 Triton™ Corrosion-Resistant Washdown Heaters (European Certification)

European variant of CR1 Triton, adapted for 50 Hz and registered to European standards.

European variant of CR1 Triton, adapted for 50 Hz and registered to European standards.

• IP55 enclosure for increased safety and protection against water penetration.

• 41 models offered in 2.5 – 40 kW, ranging from 220 – 690V.

• UL listed, CE and EAC approved for global markets.

Forced Air Unit Heaters

RGE Regular Duty Air Unit Heaters

Designed for use in regular duty industrial and commercial space heating applications such as factories, parking garages, stores, etc.

Designed for use in regular duty industrial and commercial space heating applications such as factories, parking garages, stores, etc.

• Phosphate coated, epoxy painted 18 gauge steel cabinet.

• Numerous optional factory installed features to meet specific customer requirements, including optional thermostats and controls, and optional wall bracket.

• 35 models offered in 2 – 40 kW, ranging from 208 – 600V.

• CSAUS and EAC approved.

RGX Heavy Duty Air Unit Heaters

Designed for heavy duty use in non-hazardous industrial locations.

Designed for heavy duty use in non-hazardous industrial locations.

• Heavy duty construction reduces the downtime and maintenance costs associated with standard design heaters.

• 18 models offered in 15 – 50 kW, ranging from 208 – 600V.

• 40 kW and 50 kW units incorporate split loads (50%) for remotely controlled energy management systems.

• CSAUS and EAC approved.

Duct Heaters

RXDF Explosion-Proof Duct Heaters

Designed for heating air or gases in hazardous locations such as oil refineries, coal mines, petrochemical plants, etc., where potentially explosive substances are present.

Designed for heating air or gases in hazardous locations such as oil refineries, coal mines, petrochemical plants, etc., where potentially explosive substances are present.

• Heavy walled carbon steel finned tubular (Calrod Type) elements with nickel plated finish to provide safe, efficient, low temperature heat transfer.

• Models offered in 2.5 – 50 kW, ranging from 208 – 600V.

• Available with T2D, T3A or T3B hazardous area temperature codes.

• CSAUS and EAC approved.

Types RDFF, RDIF, RDFT & RDIT Air Duct Heaters

Designed for use in comfort heating applications such as make-up air heating, air pre-heating, air handling equipment, etc.

Designed for use in comfort heating applications such as make-up air heating, air pre-heating, air handling equipment, etc.

• RDFF is a Flanged Duct Heater with finned tubular (Calrod® type) elements.

• RDFT is a Flanged Duct Heater with non-finned tubular (Calrod® type) elements.

• RDIF is an Insert Duct Heater with finned tubular (Calrod® type) elements.

• RDIT is an Insert Duct Heater with non-finned tubular (Calrod® type) elements.

• Auto reset primary and manual reset secondary linear cutouts.

• CSAUS approved.

Explosion-Proof Exhaust Fans

EFX Explosion-Proof Exhaust Fan

Designed for both hazardous location and general purpose industrial applications.

Designed for both hazardous location and general purpose industrial applications.• 12 – 30" fan sizes, up to 6,600 CFM.

• Optional features include backdraft dampers, rain hoods and Heresite® coating on all non-motor components.

• Spark resistant aluminum fan blades for hazardous locations.

• Epoxy-coated steel construction.

• Fan guards conform to OSHA specifications.

• Models ranging from 115 – 575V.

• Motors are CSA and EAC approved and/or UL listed.

• Hazardous ratings: Class I, Divisions 1 & 2, Groups C, D; Class II, Divisions 1 & 2, Group E, F, G.