Heating cables

Series constant watt heating cable Thermon TEK

Long Line Temperature Maintenance or Freeze Protection TEK series resistance constant watt heating cables are used where circuit lengths exceed the limitations of parallel resistance heating cables. Circuit lengths up to 12,000 feet (3,658 m) can be energized from a single power supply point.

Long Line Temperature Maintenance or Freeze Protection TEK series resistance constant watt heating cables are used where circuit lengths exceed the limitations of parallel resistance heating cables. Circuit lengths up to 12,000 feet (3,658 m) can be energized from a single power supply point.

The series circuitry of TEK provides consistent watt-per-foot power output along the entire length of the cable with no voltage drop.

Features Thermon-TEK

- Long line freeze protection

- Long line process temperature maintenance

- No steam clean

- Certified for use in ordinary (nonclassified) areas and in potentially explosive atmospheres

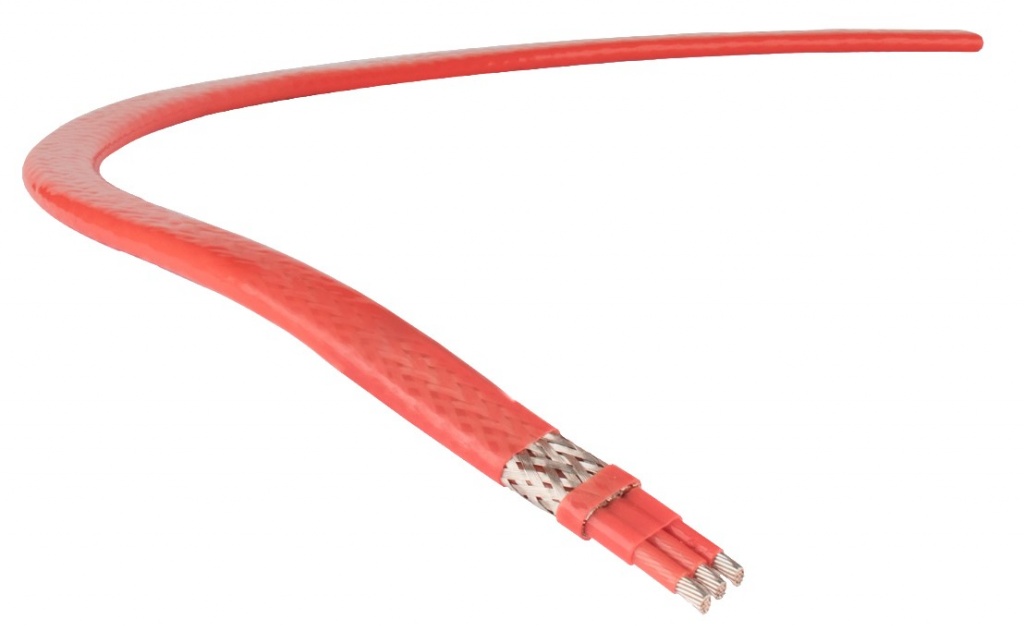

Construction Thermon TEK

1. Heating conductors (2 или 3)

1. Heating conductors (2 или 3)

2. Fluoropolymer dielectric insulation

3. Fluoropolymer pairing jacket

4. Nickel-plated copper braid

5. Fluoropolymer overjacket provides additional protection for cable and braid where exposure to chemicals or corrosives is expected.

Ratings Thermon TEK

- Rated voltage: for operation up to 600 Vac

- Max. maintenance temperature: 215°F (101°C)

- Max. continuous exposure temperature:

Power-off: 450°F (232°C) - Minimum installation temperature: - 60°F (- 51°C)

- Minimum bend radius:

5°F (- 15°C): 0.875” (22mm)

- 76°F (- 60°C): 1.25” (32 mm)

Available cables

| Catalog number | Resistance per conductor at 68°F (20°C) | Conductor size | |

|---|---|---|---|

| 2 conductor | 3 conductor | Оhms/m | |

| TEK 2C40 | TEK 3C40 | 0.01492 | 16 AWG |

| TEK 2C50 | TEK 3C50 | 0.009449 | 12 AWG |

| TEK 2C60 | TEK 3C60 | 0.005945 | 14 AWG |

| TEK 2C70 | TEK 3C70 | 0.003478 | 10 AWG |

Terminations and splices

Prior to connection to power, TEK heating cables should be terminated using the Terminator DP-M, ZP-M or with an appropriate nonheating “cold lead” and a “hot-end” termination. To facilitate ease of installation and accommodate standard shipping lengths, in-line splices may also be required. These connections/terminations are available as factory fabricated assemblies or as field fabricated kits.

Power connection

Provides fluoropolymer insulated nickel-plated stranded copper cold leads and ground wire extension plus required butt lug splices, insulating tape and sealant. A flexible stainless steel conduit that ends in a 3/4” fitting protects the leads. The number and size of the cold leads is based on the TEK heater type.

Provides fluoropolymer insulated nickel-plated stranded copper cold leads and ground wire extension plus required butt lug splices, insulating tape and sealant. A flexible stainless steel conduit that ends in a 3/4” fitting protects the leads. The number and size of the cold leads is based on the TEK heater type.

End termination

The hot end (opposite end from power) utilizes an under insulation stainless steel fitting that houses the connector lug, insulating tape, sealant and grounding lug. The size and style of the termination is based on the number and size of conductors.

The hot end (opposite end from power) utilizes an under insulation stainless steel fitting that houses the connector lug, insulating tape, sealant and grounding lug. The size and style of the termination is based on the number and size of conductors.

In-line splices

When the circuit length exceeds the practical length of a cable reel or to facilitate the installation of the cable, an under insulation splice may be required. The splice utilizes a stainless steel housing (sized for the conductor type and number), butt lug splices, grounding lugs, insulating tape and sealant.

When the circuit length exceeds the practical length of a cable reel or to facilitate the installation of the cable, an under insulation splice may be required. The splice utilizes a stainless steel housing (sized for the conductor type and number), butt lug splices, grounding lugs, insulating tape and sealant.

Terminator ZP-M

Designed to fabricate power connections, in-line splice connections or for making end terminations. Electrical connections are made in terminal blocks utilizing nickel-plated copper terminals to ensure corrosion-free electrical integrity.No cold leads are required.

Designed to fabricate power connections, in-line splice connections or for making end terminations. Electrical connections are made in terminal blocks utilizing nickel-plated copper terminals to ensure corrosion-free electrical integrity.No cold leads are required.